Continuing with the Lee products reviews here is one that did not survive for long and was discontinued some time ago. The "Lee Speed Die" was Lee's answer to try and replace a 3 die set with one single die, or was it? Lets take a look at a .357 Magnum Carbide Speed die and see how well this was thought out.

The Lee speed die ad line is as follows "One die replaces three. The first significant pistol die breakthrough since the carbide die. When used in any single station press, the Lee Speed Die reloads faster than three die sets because you don't have to change dies between operations. Carbide Speed Die, shellholder, powder measure and loading data included."

|

| L-R Carbide sizing ring, die body, decapper/flare stem and seater stem. |

The die is basically made up of 4 major components, the carbide sizer ring, die body, decap/flare stem and seater stem. The carbide sizer ring screws into the bottom of the body and the two stems are placed into the top as needed. This die is well thought out from a engineering stand point I believe. The decap stem is from what I can tell the only thing that makes this a .357 Magnum die set in that the decap stem has a set length from where it would bottom out in the case and the upper stem where it gives a VERY slight flare to the bell the case mouth NOT TRUE, read here to see what I've learned about their differences . OK, so those are the parts let us see this dog can hunt.

|

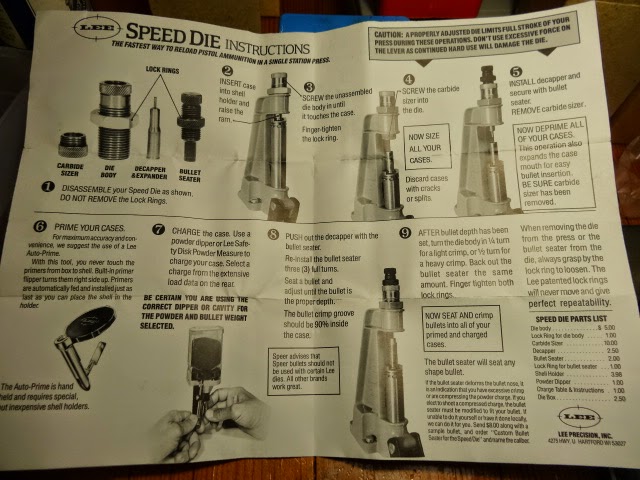

| Provided instruction sheet- a link to the PDF version of this is provided at the bottom of this post |

Next we install the carbide sizer ring and we FL size all of our brass, in this abbreviated test I am sizing 15 pieces of various .357 Mag brass all range pick up that are all various sizes. After sizing the brass I measure the OD of them and compare with my other 3 die sets...exact same OD on both, in fact with the way the carbide sizing die ring is set up it seemed like it sized further down on the case even. On other die sets the carbide ring is recessed a little to protect the carbide, so failure of this component is a concern if die is not set up correctly.

After our 15 pieces of brass are sized we remove the carbide ring (with die body still in place) this is what makes it a "speed die" remember!? We move on to decap/flaring.

Next in following the directions we drop in the decapper and secure with the bullet seater

|

| Bullet seater threaded on top holds decapper in place. Position is not critical |

From here we decap/flare our 15 pieces of brass. Some Lee fans out there might know that the Lee loader (whack a mole type) for the .357 and .38 use all the same components in the kit EXCEPT for the load data and powder dipper (whack a mole review coming soon). This kind of utility is a boon to the minimalist, so I started thinking "what makes this speed die a .357 mag specific set and it dawned on me The decap/flare stem is the only caliber specific component for this die, a body could make another decap/flare stem and be set for .38 special as well....in theory. I'll report back later on this....NOT TRUE! click here to read what I have learned about their differences

Basically what I'm saying at least in theory as I have not had a chance to compare it with the .38spl speed die I also acquired, is that all you need to make your .357 magnum speed die into a .38spl speed die is the appropriate proportioned decap/flare stem.....something to think about.

Sorry, got sidetracked, lets finish up this batch of 15 rounds, we have sized, decapped and flared our brass, now we need to prime it. For this I will use the Lee Ram Prime tool which forces us to change out the die...they want you to use a Lee Auto-prime in the instructions but I only have a fancy RCBS priming unit and it takes more time to mount it on the bench than setting up the lee ram prime so the lee prime it is. If you are interested in the Lee primer unit there is a review one post down from this review.

After we have primed our cases with appropriate primers we are ready to weigh out powder charges, charge the cases and seat the bullets. I am seating 125gr jacketed bullets on top of a healthy charge of 16.8gr of 2400, this has proven to be a pretty good flame thrower load out of my guns and is fun to shoot towards the end of range sessions. The bullet seater is easy to adjust however as mentioned in the instructions you must turn the die body in 1/4 for light crimping and 1/2 turn for heavy crimping which is usually suggested with light bullets on top of slower powders that take up a lot of case space.

A note on seating, A page on lee's website mentions the die is not to be used with cast bullets. I find this somewhat odd as I don't really see why that would be a issue. The only thing I can come up with is the decapper/flare stem does not bell the case an appreciable amount needed for cast bullets. In fact it is just barely enough for the jacketed bullets I was using and some care must be taken to insure the bullet is started correctly or you run a risk of ruining the case. I see no reason why you couldn't flare the case a little more and seat cast bullets with this die set....er this die. Maybe we're starting to see exactly why this particular line of reloading equipment was discontinued. It's is great for the minimalist wanting a step up from the lee loader whack a mole type dies but not wanting to have to mess with 3 dies, say a guy who has a S&W 686 that needs 100 rounds a month for matches and or plinking and is loading on his coffee table. I am not sure what the original MSRP was on the speed die compared to other 3 die (or 4 die sets) of the same manufacture. I'm willing to guess it was at least half or 3/4 of the cost of a full die set. But say you wanted to add on a lee universal flare die so you could load cast bullets with this die.....at that point you might as well start looking at the regular carbide 3 die sets.

As per Lee's website

Speed dies were discontinued in the late 90's.

The Speed die does everything a 3-die set does by combining some steps, and by providing a removable carbide-sizing ring. When used in a single stage press, the Speed die is faster because one doesn't need to keep changing die bodies to perform different tasks. Simply swapping internal components accomplishes the same thing. The speed dies can only be used for jacketed bullets, can't be used for cast bullets.

Cartridges that were available at one time:

- 9mm Luger

- 38 Special

- 357 Mag

- 44 Mag

- 45 ACP

Conclusion- The Lee Speed die I'm sure was met with some trepidation at its unveiling to the reloading public. Replacing 3 dies with one for the sake of speed was not the pitch I would have used to sell this product. The fact it was offered in probably the 5 highest selling calibers should have helped but it still was discontinued most likely to people not really sure the best way to use this die, or perhaps expected too much from it. These dies sell around $30 or so when found I have seen, so obviously some people have found a way to utilize the die. I myself will keep mine under the bench to go along with my hand press when I head to the range with plans to load test ammo on site. The 15 rounds we loaded all look very consistent, in fact with the way the decap/flare stem works its impossible to over bell the case mouths so brass should last a little longer. The crimps are consistent and the bullets all seated at the same depths....I'm very happy with the results.I would in fact say that yes 1 die CAN replace 3 however this one die does not have the versatility that 3 can provide...now for the weather to clear up and some range time to take place. The bullets I used in these loads were pulled bullets so it wont be fair to measure accuracy on target and compare results with like loads from 3 or 4 die sets as some of their noses were slightly deformed from being pulled down. If you are a minimalist and wish to not accumulate a great many dies and accessories I believe it may be worth your while to try to track down a Lee Speed die if you are looking to reload for only one caliber (and hopefully its one of the 5 calibers they made). Stay safe out there!